Generation Laser

PROVIDE LASER EQUIPMENT

PROVIDE TRUE VALUE

Generation Laser is a laser equipment manufacturer composed of experienced technicians and top European salesmen. By controlling the high-quality supply chain and sophisticated manufacturing technology, we have built machines that meet European standards.

Based in Italy, our service coverage covers the European Union. With fast and excellent after-sales service as our competitiveness, we provide customers with excellent machines, reasonable prices and high-quality after-sales service. To ensure service quality, we have built a spare parts warehouse to solve customer problems in the first place.

QUALITY AFTER SALE

We are known for our fast service response time. 7-18-30 after-sales service system to ensure customers high input-output ratio.

Professional Team Worker

We bring the right people together to challenge established thinking and drive transform

-1-768x433.png)

Professional Worker

We gather young but experienced workers to ensure high-quality installation processes.

WHat We Do

Company Service

We provide high-quality pre-sales and after-sales services and the most suitable solutions for our customers.

PRE SALE SERVICE

Provide technical guidance,equipment solutions and other information services according to your needs.

SELLING SERVICE

Provide installation, commissioning, and training services. Ensure the equipment is delivered on time.

AFTER-SALE SERVICE

Provide on-site maintenance services. We will establish communication group with the customers, support the daily use of customers..

our products

popular products

We focus on providing fiber laser processing equipment and its solutions. If you don’t find a product below that suits you, please contact us.

HANDHELD LASER WELDING

MACHINE

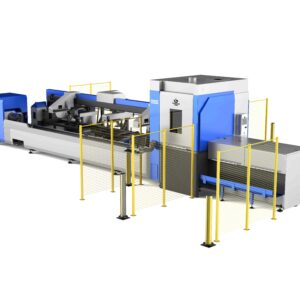

HEAVY DUTY TUBE LASER CUTTING MACHINE

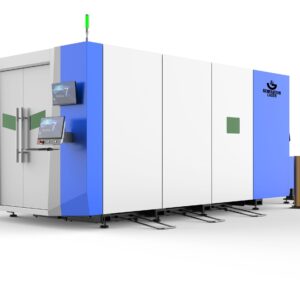

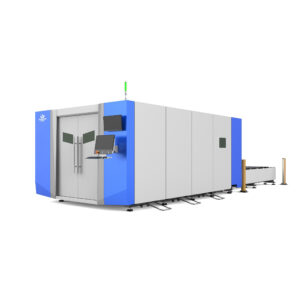

FULL ENCLOSED LASER CUTTING MACHINE

STRENGTH

WHY CHOOSE US

Our high-quality supply chain is a strong guarantee of product quality and performance.

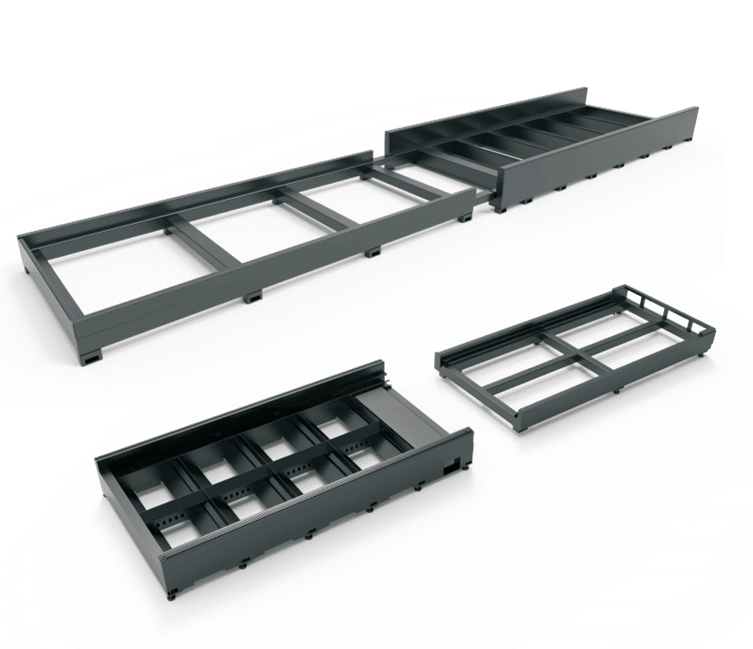

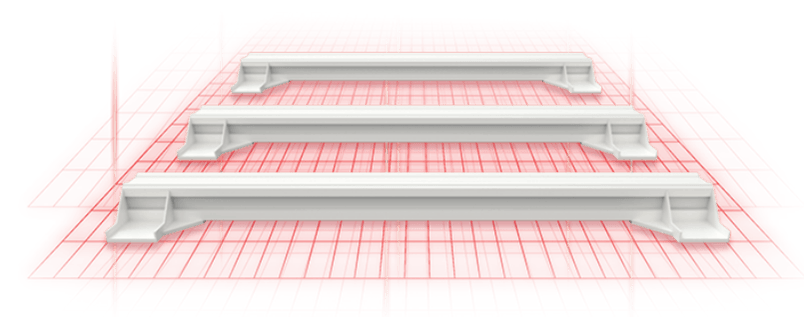

650℃ annealing Industrial Machine Bed

- Research and develop of machine bed by ourselves

- It adopts industrial-grade standard annealing process, and has undergone multiple precision manufacturing processes and multiple precision instrument tests to ensure the durability of the bed and ensure stable long-term operation without deformation.

Extrusion Aviation Aluminum Gantry

- Adopting the extruded one-piece forming process, it has high strength and can withstand heavy loads without deforming or breaking.

- It is made of high-quality aluminum material that is both lightweight and strong. This allows the laser cutting machine to move quickly and accurately while maintaining its stability during the cutting process.

- It enables the laser cutting machine to move faster, resulting in faster cutting speeds without sacrificing precision or quality.

Climbing pallet exchange

- Allows for quick platform switching in just about 15 seconds.

- Dual platforms stays at the same level after the exchange.

- Extremely low failure rate and maintenance cost.

Intelligent EtherCAT System

- It automates the laser cutting process, reducing the need for manual intervention and increasing efficiency. The system can be programmed to perform a wide range of cutting operations, allowing for greater flexibility and adaptability to different cutting requirements.

- The system provides real-time monitoring of cutting parameters, allowing operators to quickly identify and address any issues that may arise. This improves overall efficiency and reduces downtime.

intelligent and Precision Laser Cutting Head

- High-quality lenses and advanced servo motor control technology to ensure precise and accurate cuts. This results in less material waste and improved product quality.

- Modular design help to solve the problem in a short time, with low maintenance cost.

- Excellent sealing design, multiple protective lens sets.

HIGH PERFORMANCE Laser Source

- The laser sources are highly efficient, with up to 40% electrical efficiency. This reduces energy costs and increases productivity, making them a cost-effective option for industrial settings.

- It is designed for long life, with an average lifetime of more than 100,000 hours. This reduces maintenance costs and downtime, resulting in increased productivity.

Laser Cutting

What Is the Materials We Can Cut With Laser Cutting?

Based on the heat treatment characteristics of laser, it supports cutting the vast majority of common metals.

- Mild Steel

- Aluminium

- Galvanized

- Stainless Steel

- Brass

- Copper

Testimonial

What Our Client Says

We provide reliable, accurate, high-performance laser processing solutions and provide excellent after-sales service that is well above industry standards.